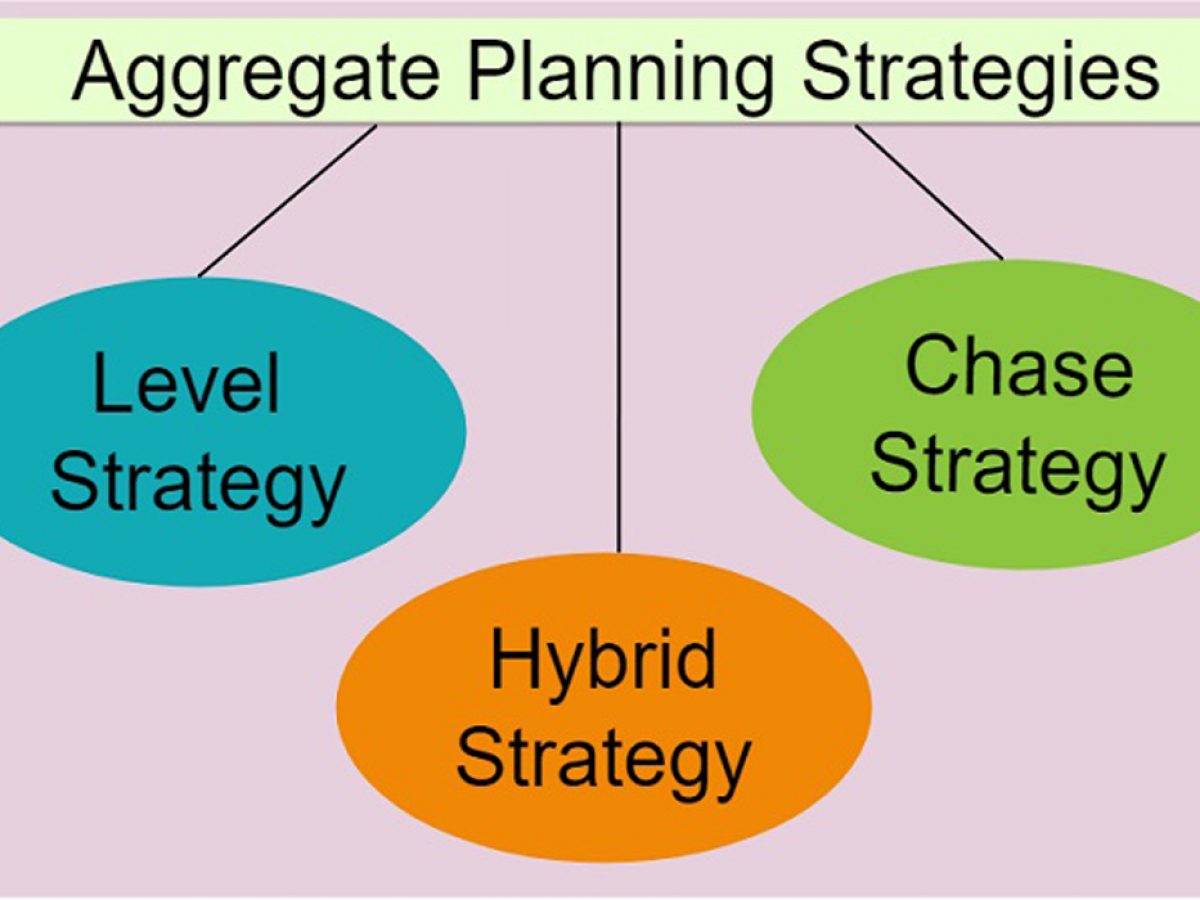

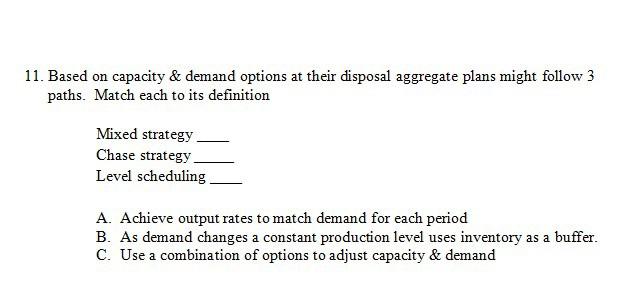

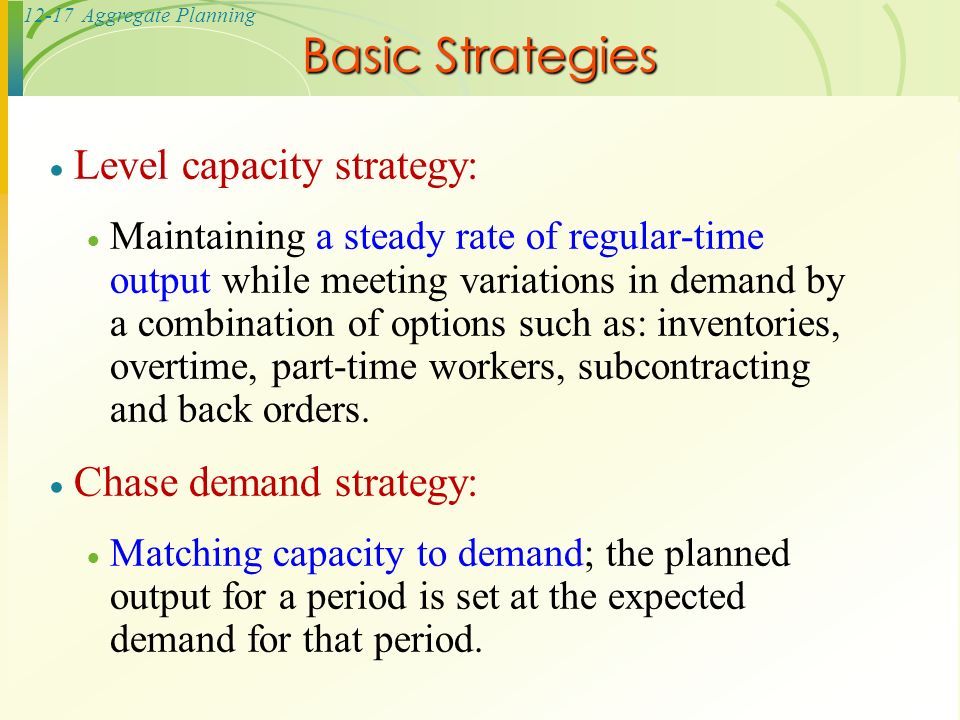

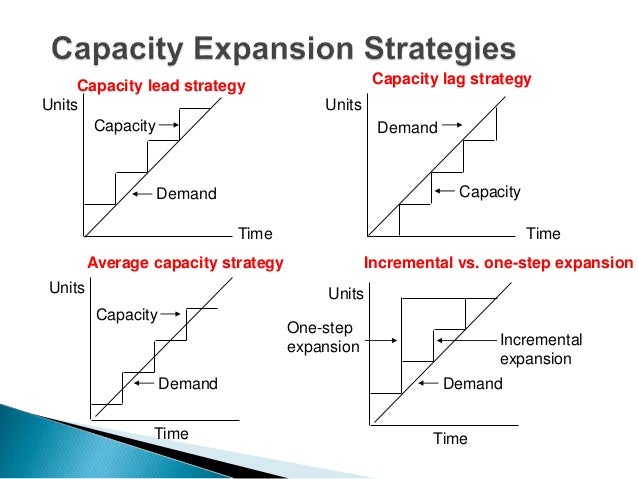

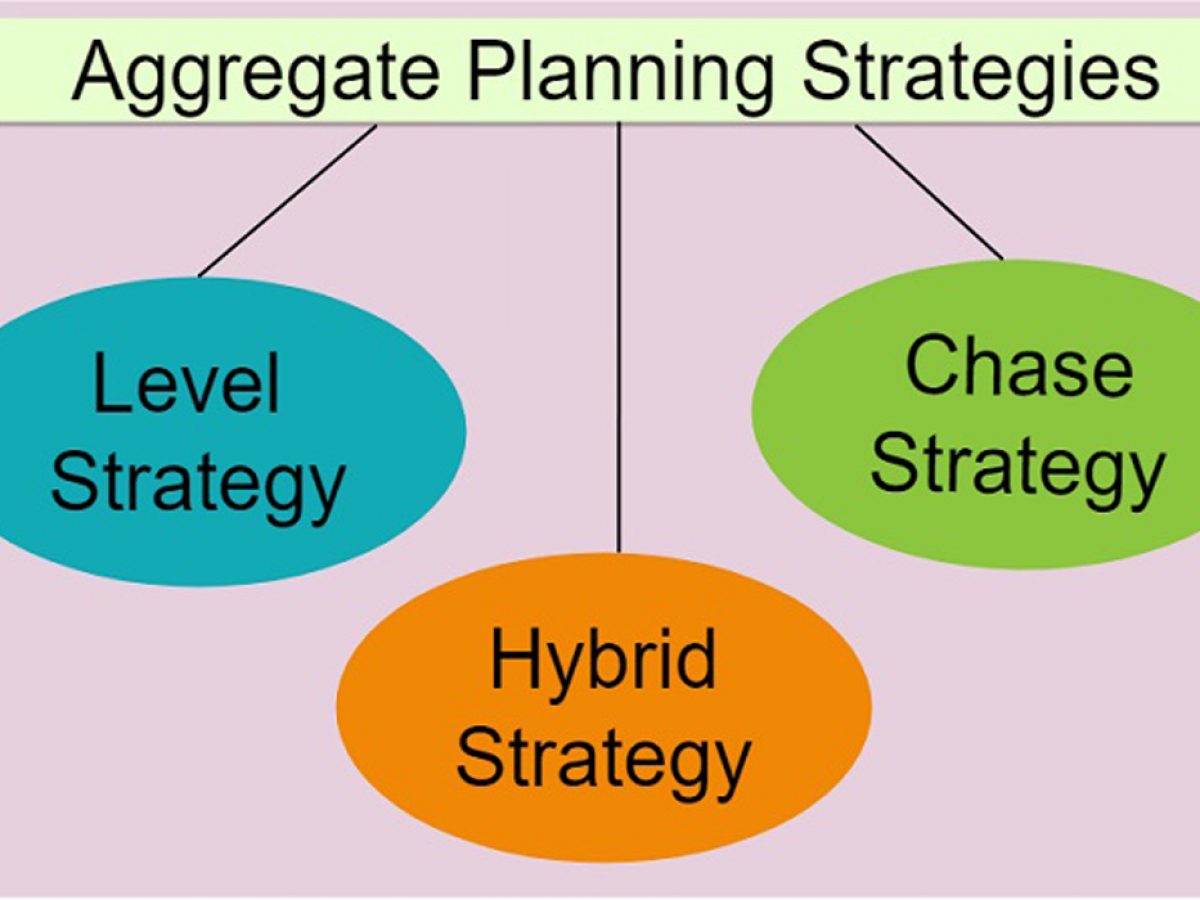

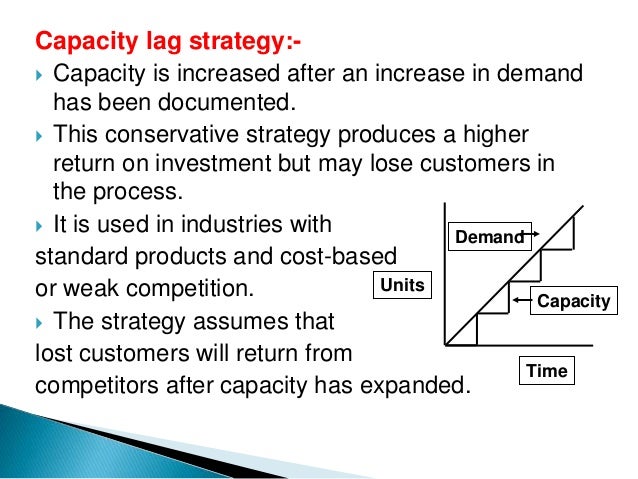

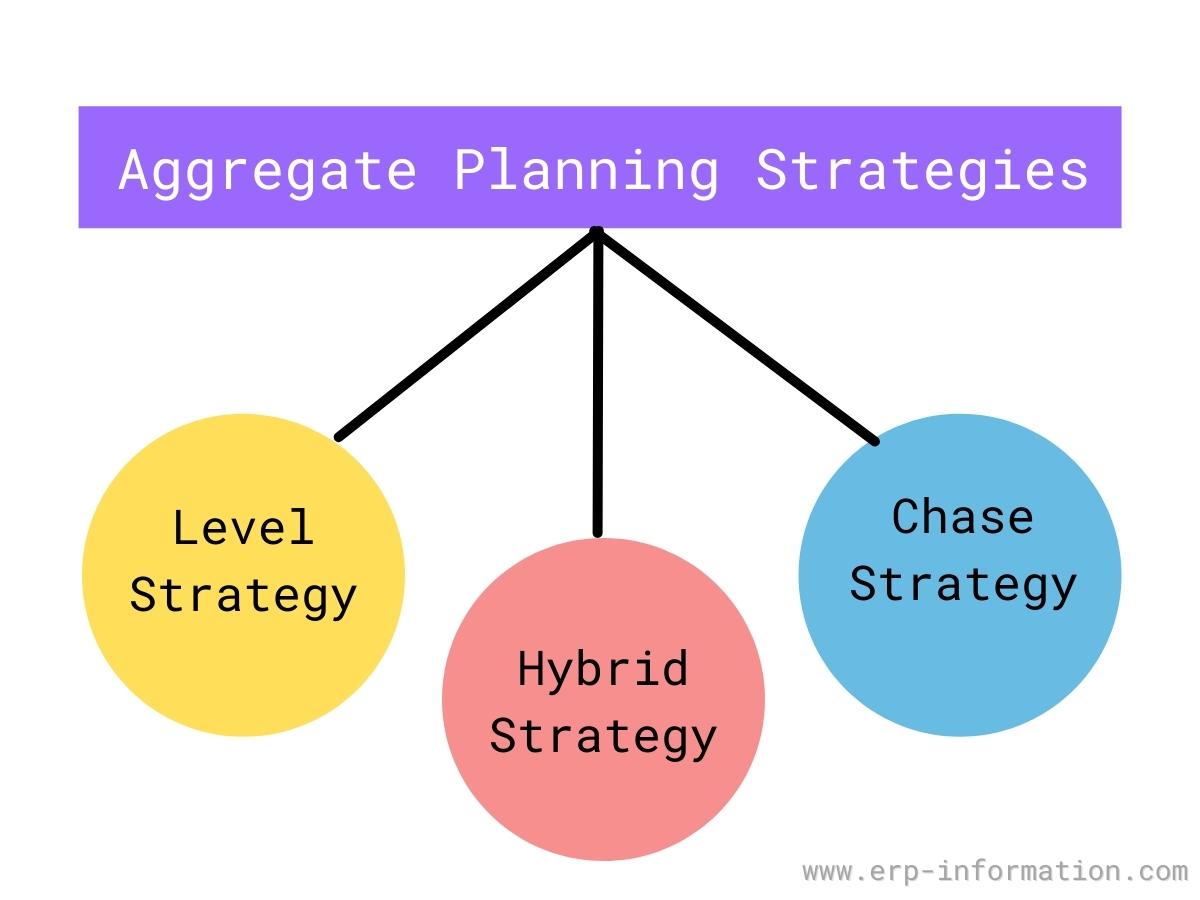

In other words, Manager A is tied to the "chase demand" strategy, and his counterpart, Manager B in the adjacent office, is locked into the "level capacity" strategyWith the level strategy, production remains at a constant level in spite of demand variations In companies that produce to stock, this means that finished goods inventory levels will grow during low demand periods and decrease during highLag strategy is a conservative method of capacity planning that ensures your costs are as low as possible The potential downside to this strategy is that it can create a lag in the delivery of products or services to customers, which is where the name comes from

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

What is level capacity strategy

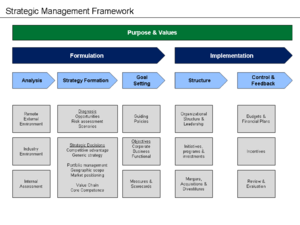

What is level capacity strategy-Strategic thinking is defined as the individual's capacity for thinking conceptually, imaginatively, systematically, and opportunistically with regard to the attainment of success in the future Strategic thinking is not the same thing as critical thinking Strategic thinking is better thought of as a style of thinking and not confused with organizational techniques or processesUp to10%cash backThe use of a level strategy means that a company will produce at a constant rate regardless of the demand level In companies that produce to stock, this means that finished goods inventory levels will grow during low demand periods and decrease during high demand periods

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

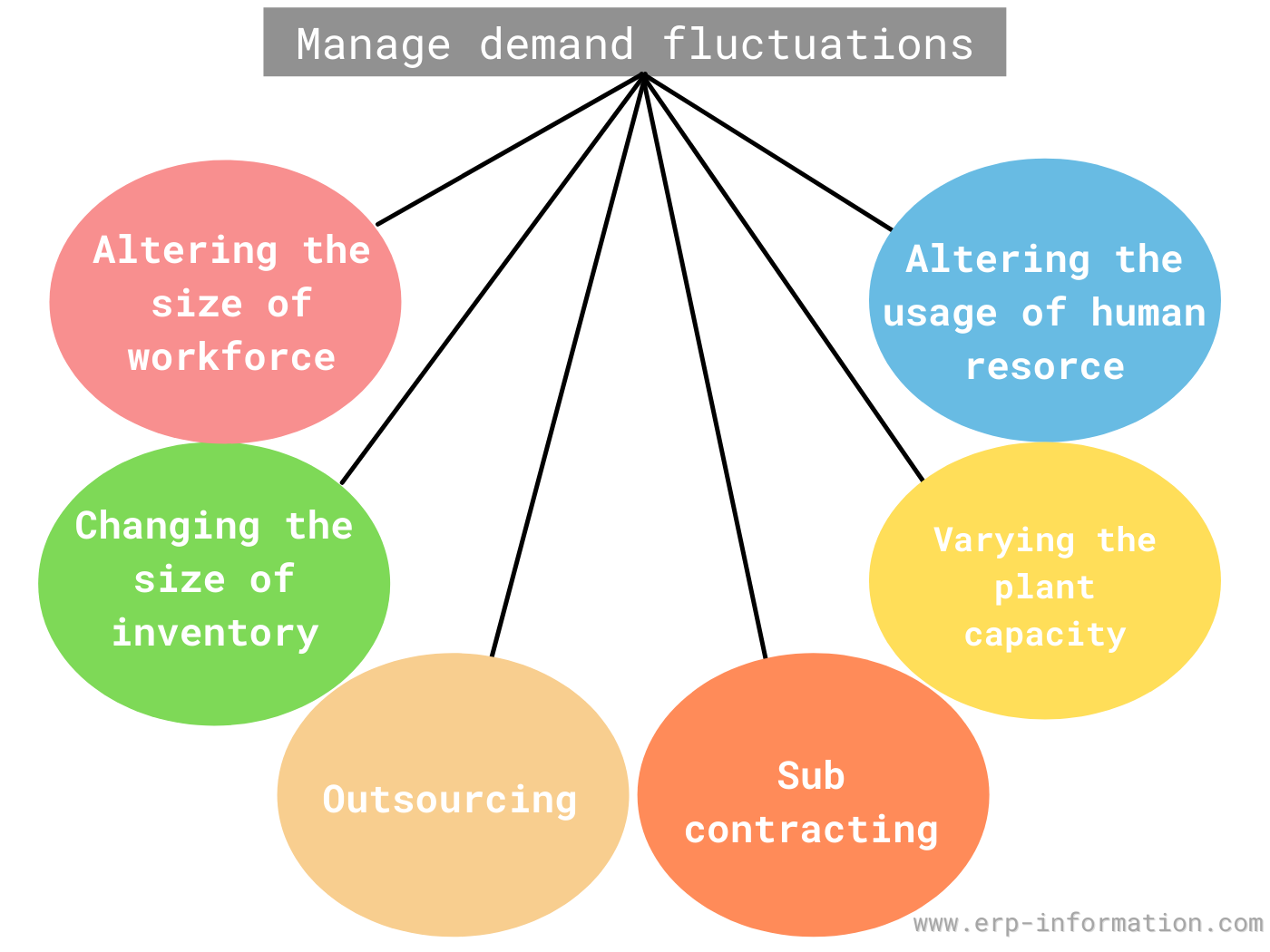

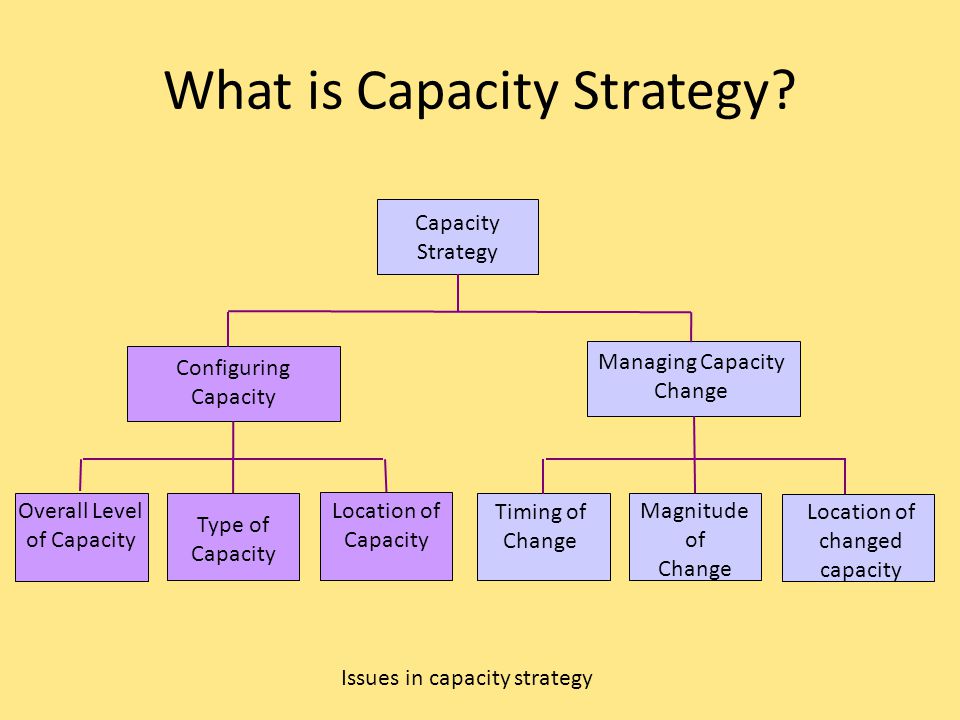

The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to followCapacity development responsibilities under one umbrella to tackle some of the systemic in order capacity constraints and address new capacity emanating from the new programme elements needs This CD Strategy provides a framework to coordinate and implement CD in a systematic and efficient mannerCapacity strategy is an approach to increasing and decreasing business capacity to meet demand Capacity includes things like labor and equipment that can be scaled to increase business output The following are common types of capacity strategy

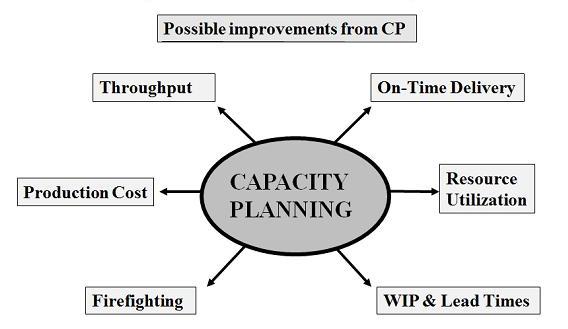

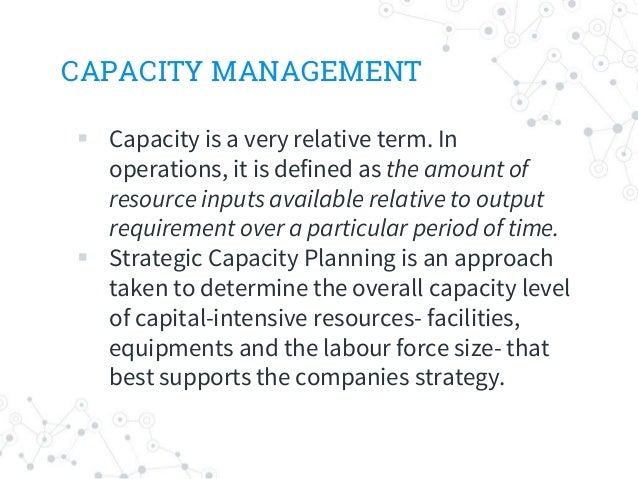

Strategies for Managing Capacity Capacity management tools and methodologies vary, ranging from manually compiled performance spreadsheets to specially compiled hardware or software that is designed to produce detailed insights on the functioning of computing componentsThis definition focuses on alpha generation at the margin, identifying capacity as the AUM after which a fund earns alpha below a minimum acceptable level on an additional dollar invested The alpha threshold represents the minimum alpha required by investors to cover the management fee and compensate for active riskCapacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of demand for

The chase strategy has the highest peak capacity requirement This means that facilities, both production and warehousing, will need to be larger than the other two strategies would require In addition, those facilities will not be 100% fully utilized, except for those rare occasions when you are at peak capacityLEVEL STRATEGY A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level In the context of the problem posted by you following the level strategy means incurring additional subcontracting costs at least twice This is to offset the shortfall in production because of the levelAQA, Edexcel, OCR, IB Capacity utilisation is a measure of the extent to which the productive capacity of a business is being used It can be defined as The percentage of total capacity that is actually being achieved in a given period Revision Video Calculating Capacity Utilisation Revision Video Capacity Management

2

Common Types Of Corporate Strategies Boundless Management

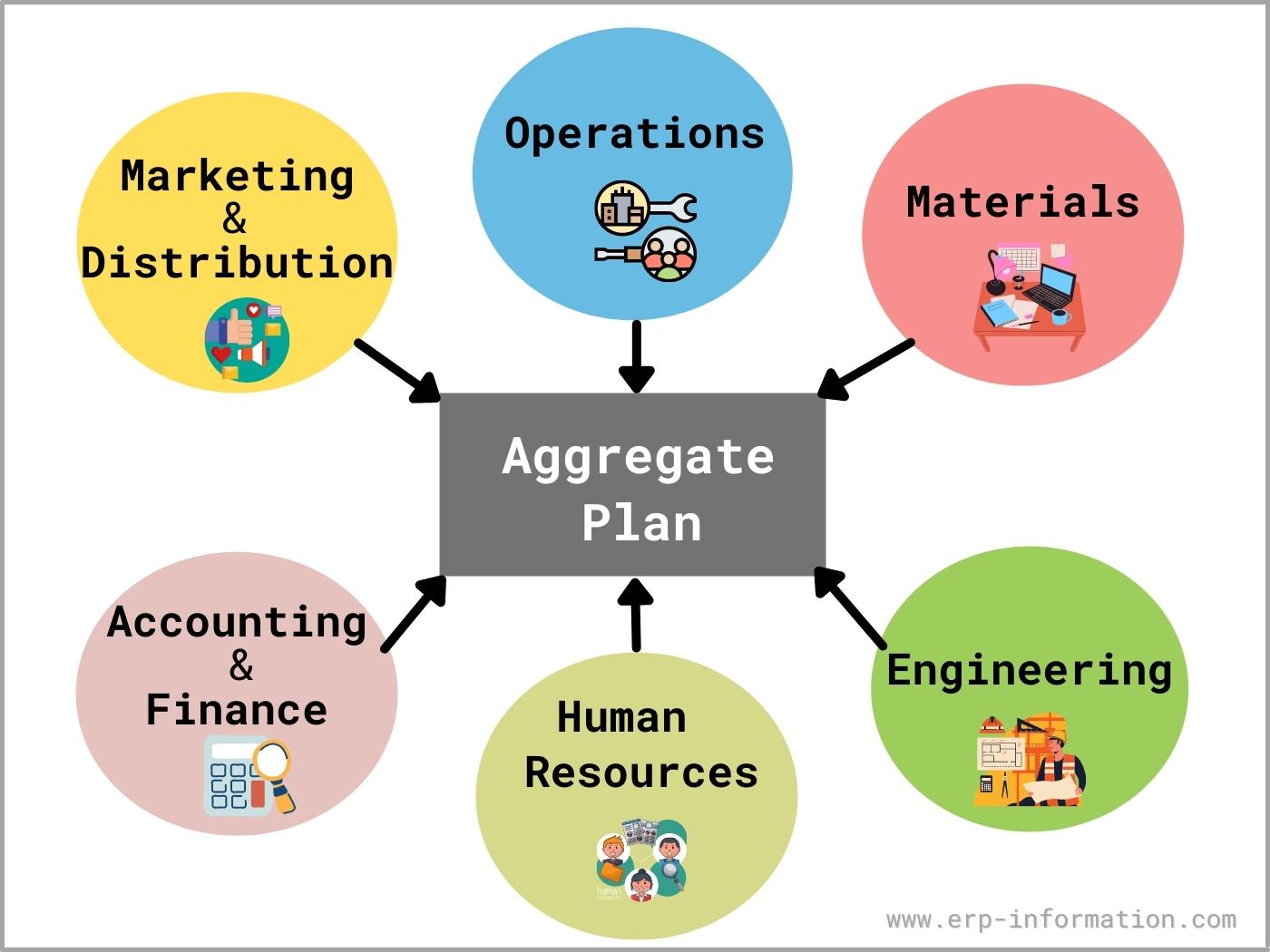

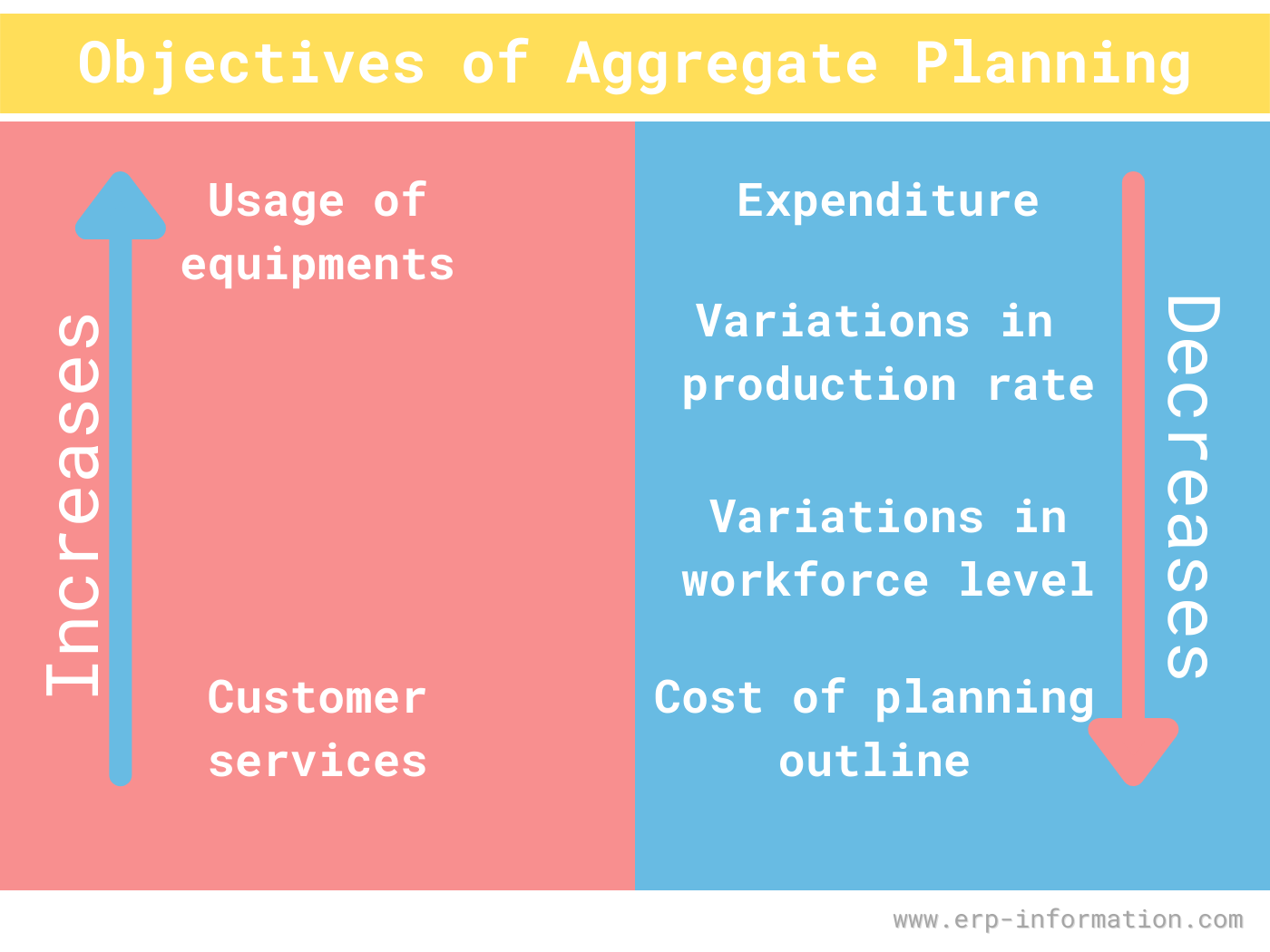

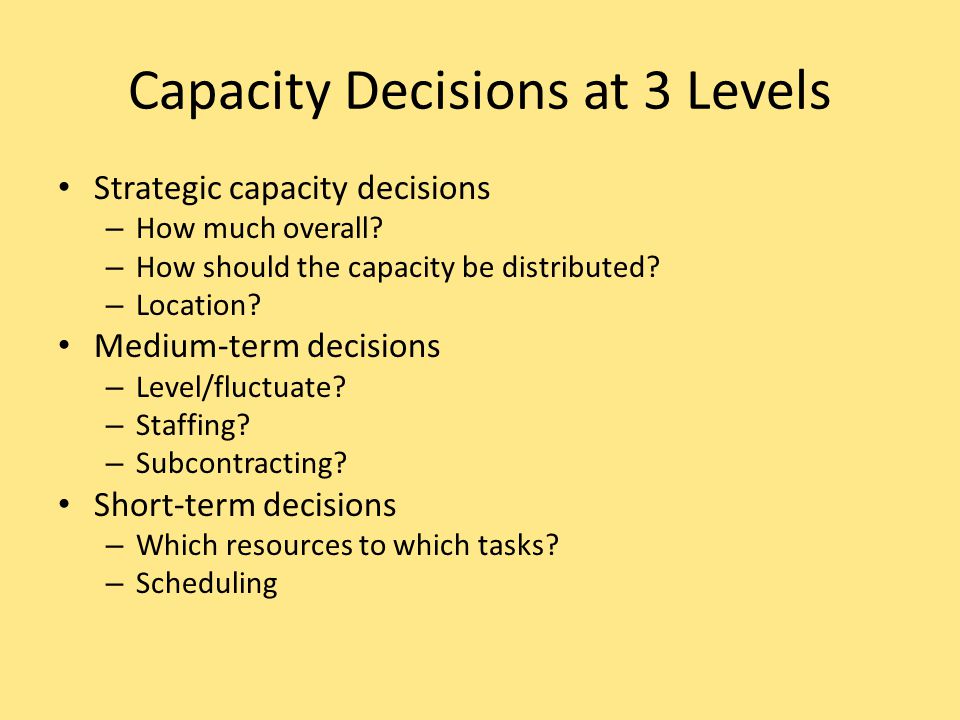

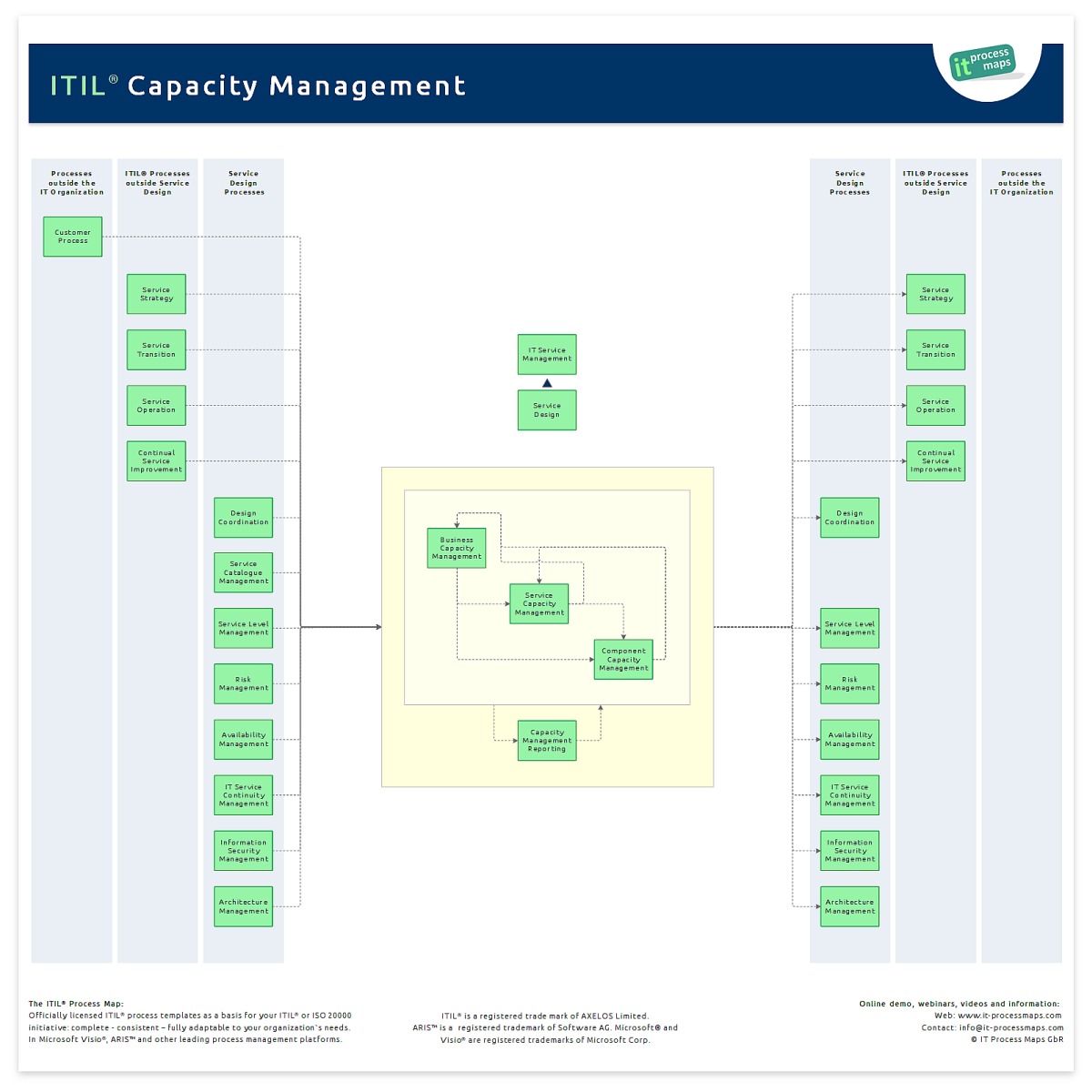

Aggregate planning is a proven technique that brings an element of foresight and stability into manufacturing It helps the management to achieve the longterm objectives of a company The importance of aggregate planning include Creates a satisfied and happy workforce Reduce changes in the levels of the workforceTypes of Corporate Level Strategy – Top 2 Types Growth Strategy and Diversification Strategy Corporate level strategy addresses the entire strategic scope of the firm It is a "big picture" view of the organisation and includes deciding in which, product or service markets to compete and in which, geographic regions to operateJohn Spacey, Capacity management is the process of planning the resources required to meet business demands This includes capacity forecasting, planning, monitoring and performance analysis This can happen at three levels in an organization

6 There Are Different Definitions Of Capacity What Chegg Com

4 Population Health Strategies That Drive Improvement

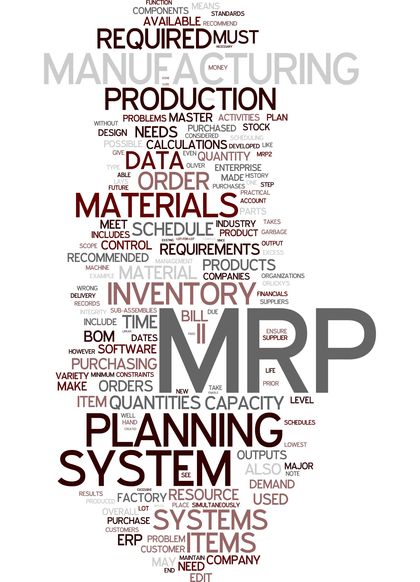

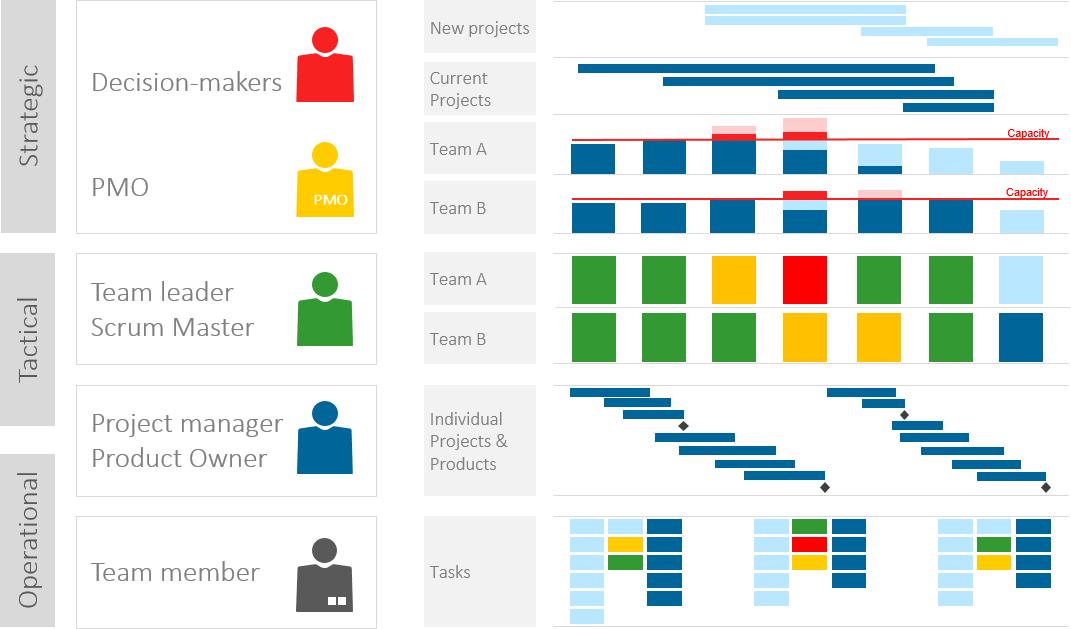

Alternative Capacity Management Strategies• Level capacity (fixed level at all times)• Stretch and shrink – offer inferior extra capacity at peaks (eg bus/metro standees) – vary seated space per customer (eg elbow room, leg room) – extend/cut hours of service• Chase demand (adjust capacity to match demand) – schedule downtimeOperations management can be defined as the planning, scheduling , and control of the activities that transform inputs into finished goods and services In other words, it is 'a field of study that focuses on the effective planning , scheduling, use, and control of a manufacturing or service organisation through the study of concepts fromCapacity planning itself has different meaning to individuals at different levels within the operations management hierarchy D The definition of capacity, in an operations management context, makes a clear distinction between efficient and inefficient use of capacity

Solved 11 Based On Capacity Demand Options At Their Di Chegg Com

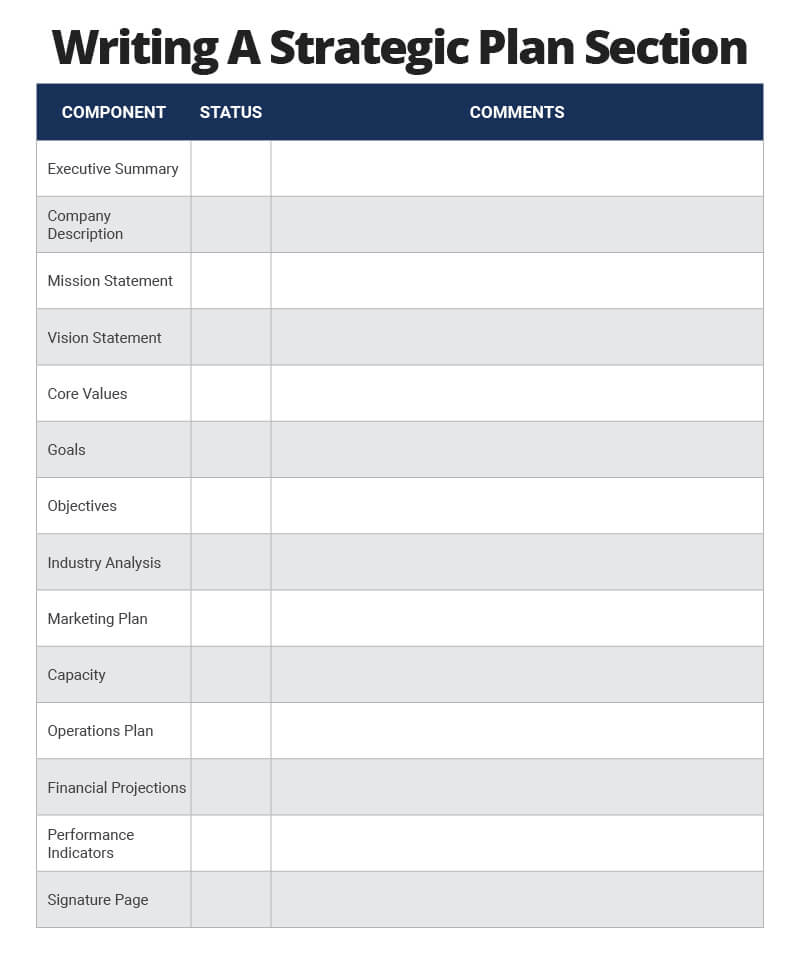

Quick Guide How To Write A Strategic Plan Smartsheet

United Nations definition of capacity development Capacity development is the process by which individuals, organizations, At the individual level, capacitybuilding involves establishing the conditions sound public capacity strategy have been described as follows "The benefitsWhen it comes to scheduling your labor force, there are two primary ways to schedule The first is called level scheduling, where you try and maintain a steady workforce with a steady schedule The second is the chase strategy, where you maintain a level workforce and increase your workforce as demand increasesFunctional level strategies will be specific and will apply to a variety of functional areas (departments) For example, building on the diversification example, the functional level strategies that support that business level strategy might be R&D Redesign product Marketing Implement new advertising plan

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

At the institutional level we help organizations strengthen their vision, strategy, structure and performance management practices Our institutional capacitydevelopment strategies make use of a range of tools and approaches, and we select strategies that are consistent with the objective, resources available and time frameAn aggressive investment strategy is a means of portfolio management that attempts to maximize returns by taking a relatively higher degree of riskLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert Johnston Level Capacity Plan Explanation

What Is Strategic Management And Why Is It Important

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

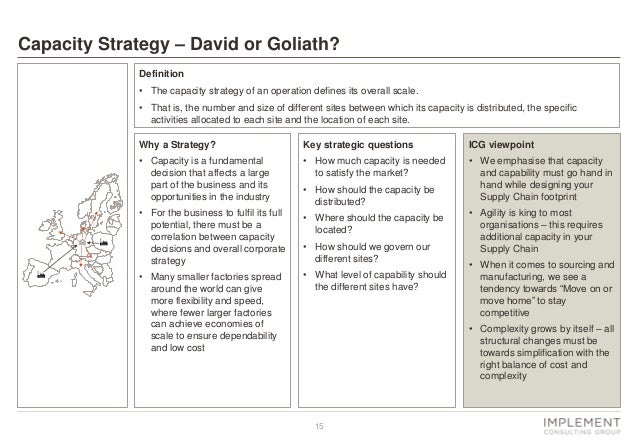

CDC's optimization strategies for PPE offer a continuum of options for use when PPE supplies are stressed, running low, or exhausted Contingency and then crisis capacity measures augment conventional capacity measures and are meant to be considered and implemented sequentiallyAs PPE availability returns to normal, healthcare facilities should promptly resumeEffective capacity is the optimum production level under predefined job and workschedules, normal machine breakdown, maintenance, etc Medium Term Capacity The strategic capacity planning undertaken by organization for 2 to 3 years of a time frame is referred to as medium term capacity planning Short Term Capacity The strategic planningCapacity expansion is a credible deterrent strategy if capacity costs are very high Otherwise, if the cost of adding capacity is low or capacity can be utilized for other purposes, it would be relatively easy for rivals to enter For example, DuPont used capacity expansion to increase its market share in the titanium dioxide market

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

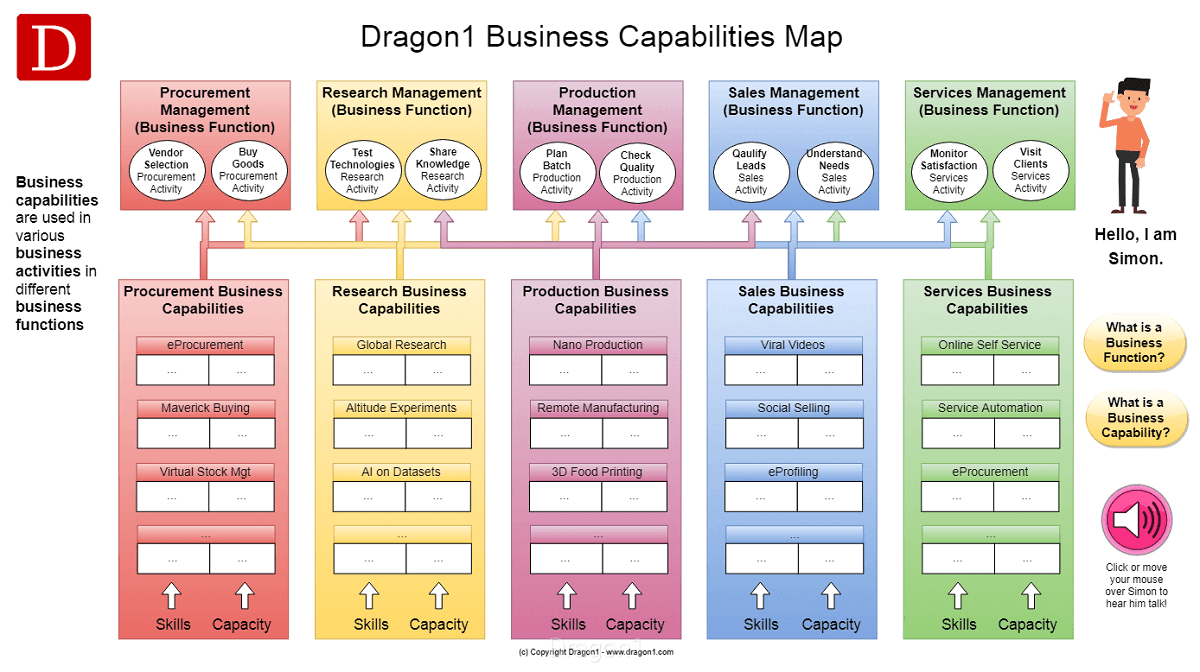

Business Capability Map And Model The Definitive Guide Leanix

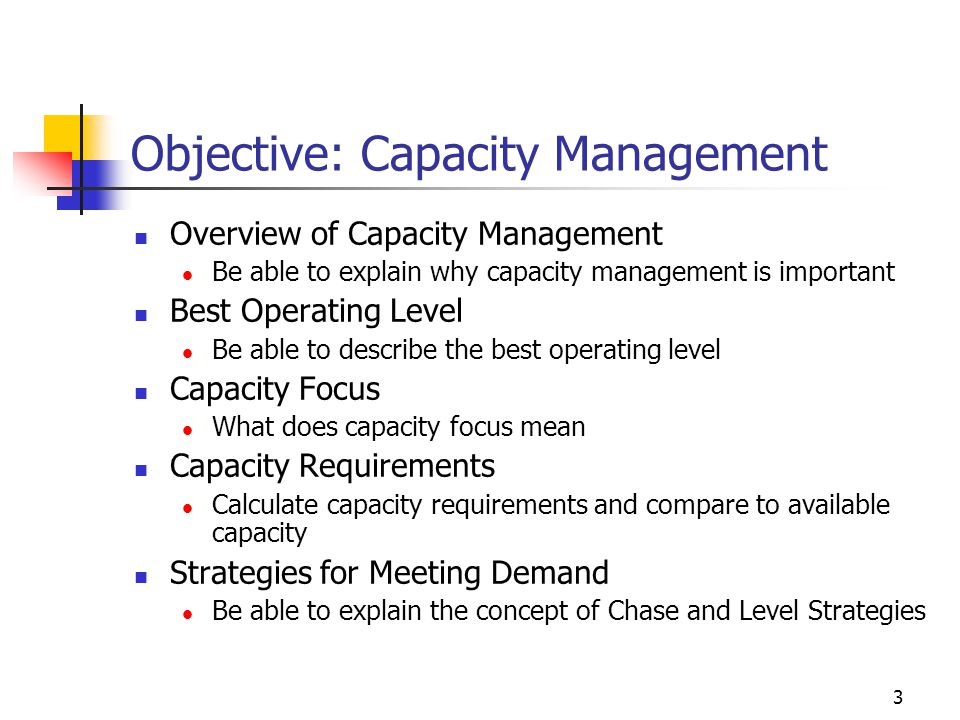

Chapter 7 Capacity Planning and Management Learning Outcomes After reading this chapter you should be able to • Define and measure capacity and appreciate the factors that influence it • Assess the difficulties of matching capacity to demand • Evaluate and apply the different strategies for matching capacity with demand in the short,Capacity planning is described as a tool to minimize the discrepancy between the capacity of a business entity and customer demands Demand for capacity is variable as it is based on changes in production output of an existing product or in the production of a new productTheoretical capacity is the amount of throughput that could be attained if a production facility were able to produce at its peak efficiency level with no downtime Theoretical capacity should not be used for planning or bonus compensation purposes, since it is nearly impossible to attain in practice Many factors can interfere with the ability

Competitive Advantage Tutor2u

2

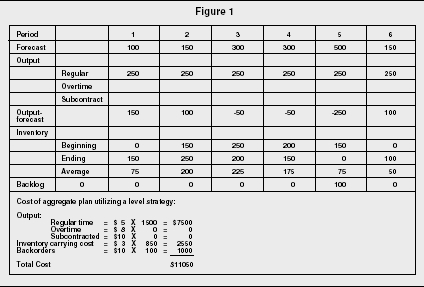

Level Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers (working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventoryAggregate planning is a marketing activity that does an aggregate plan for the production process, in advance of 6 to 18 months, to give an idea to management as to what quantity of materials and other resources are to be procured and when, so that the total cost of operations of the organization is kept to the minimum over that period The quantity of outsourcing,An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storage

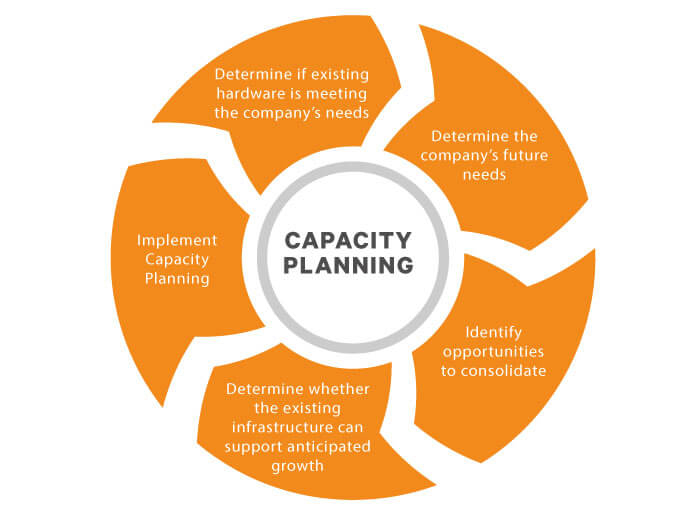

Capacity Planning Everything You Need To Know Opensense Labs

6 Elements Of Effective Strategic Planning

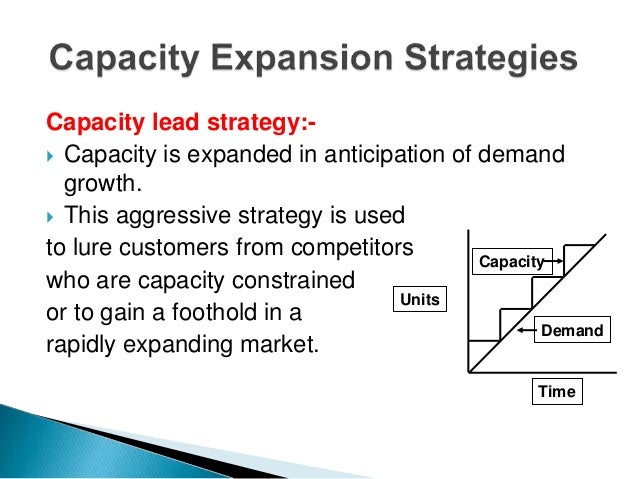

The goal of strategic capacity planningis to achieve a match between the longterm supply capabilities of an organization and the predicted level of longterm demand 3 Capacity Decisions are Strategic 1 Capacity decisions have a real impact onThat sets the overall scope for capacity development The organizational level refers to the internal structure, policies and procedures that determine an organization's effectiveness It is here that the benefits of the enabling environment are put into action and aOne of the strategic choices that a firm must make as part of its manufacturing strategy There are three commonly recognized capacity strategies lead, lag, and tracking A lead capacity strategy adds capacity in anticipation of increasing demand A lag strategy does not add capacity until the firm is operating at or beyond full capacity

Everything About Capacity Planning Strategies Its Benefits

1

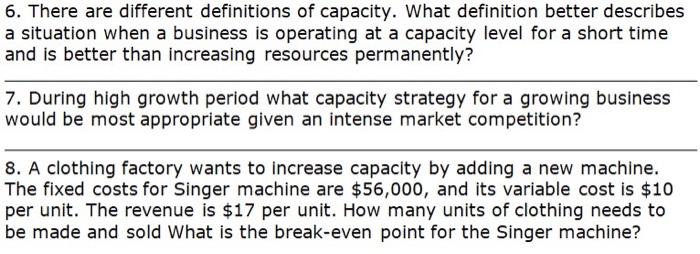

Use break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skillsCapacity Planning Approaches There are four principle methods to approach capacity planning Each method is based on reacting to or planning for market fluctuations and changing levels of demand These capacity planning strategies are match, lag, lead, and adjustment Match

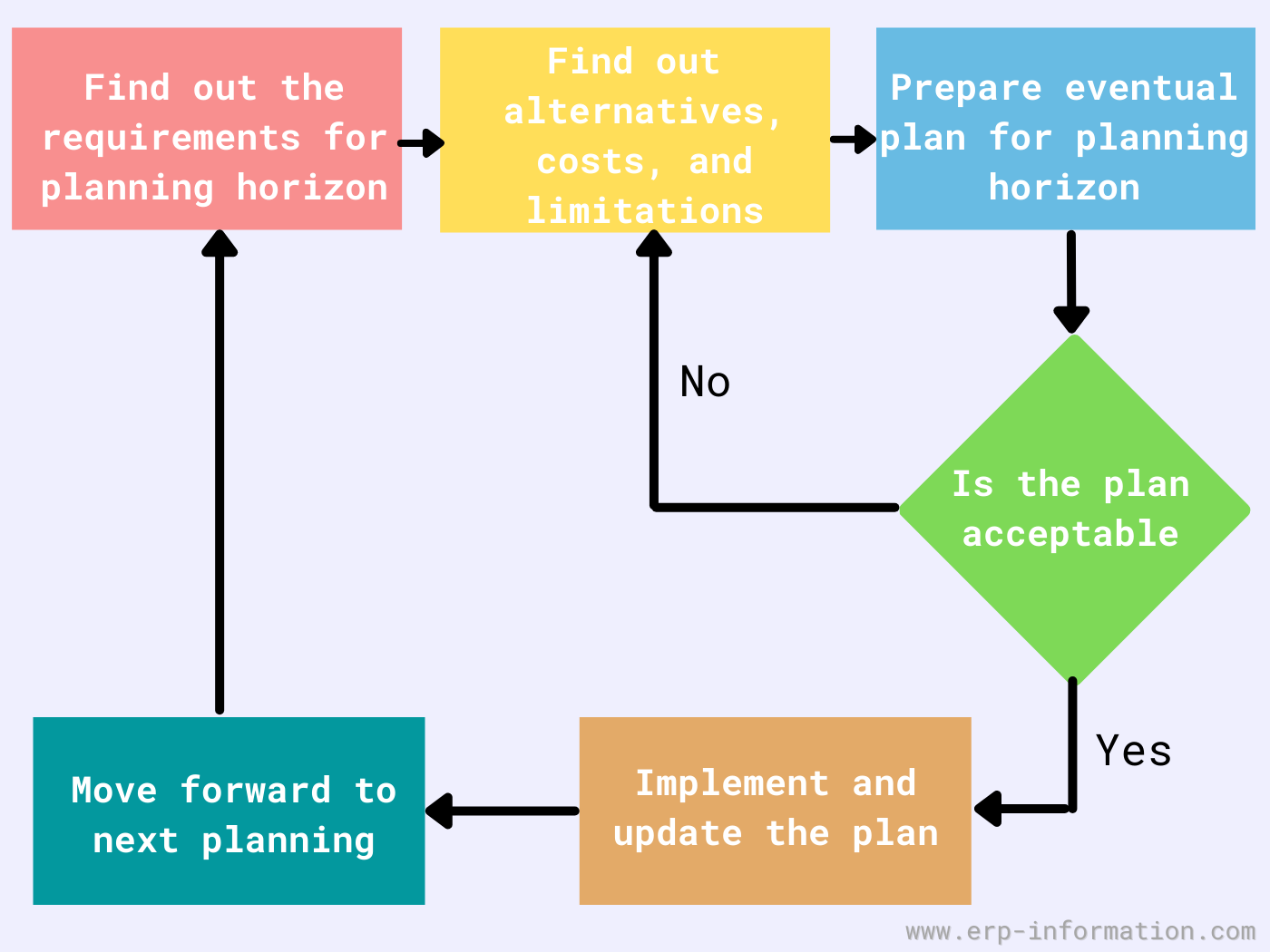

Concept Of Capacity Planning And It S Procedure Importance Management Study Hq

Increase Manufacturing Production Capacity Vorne

Capacity Utilization Manufacturing Kpi Examples Sisense

1

Operations Management Ppt Video Online Download

Capability Definition Dragon1

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

What Is Capacity Planning Examples Types Optimoroute

3 Types Of Capacity Planning Strategies Valq

Capacity Management

Operations Strategy Capacity Strategy Ppt Video Online Download

What Is Strategic Intent Apm

3 Types Of Capacity Planning Strategies Valq

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

3 Types Of Capacity Planning Strategies Valq

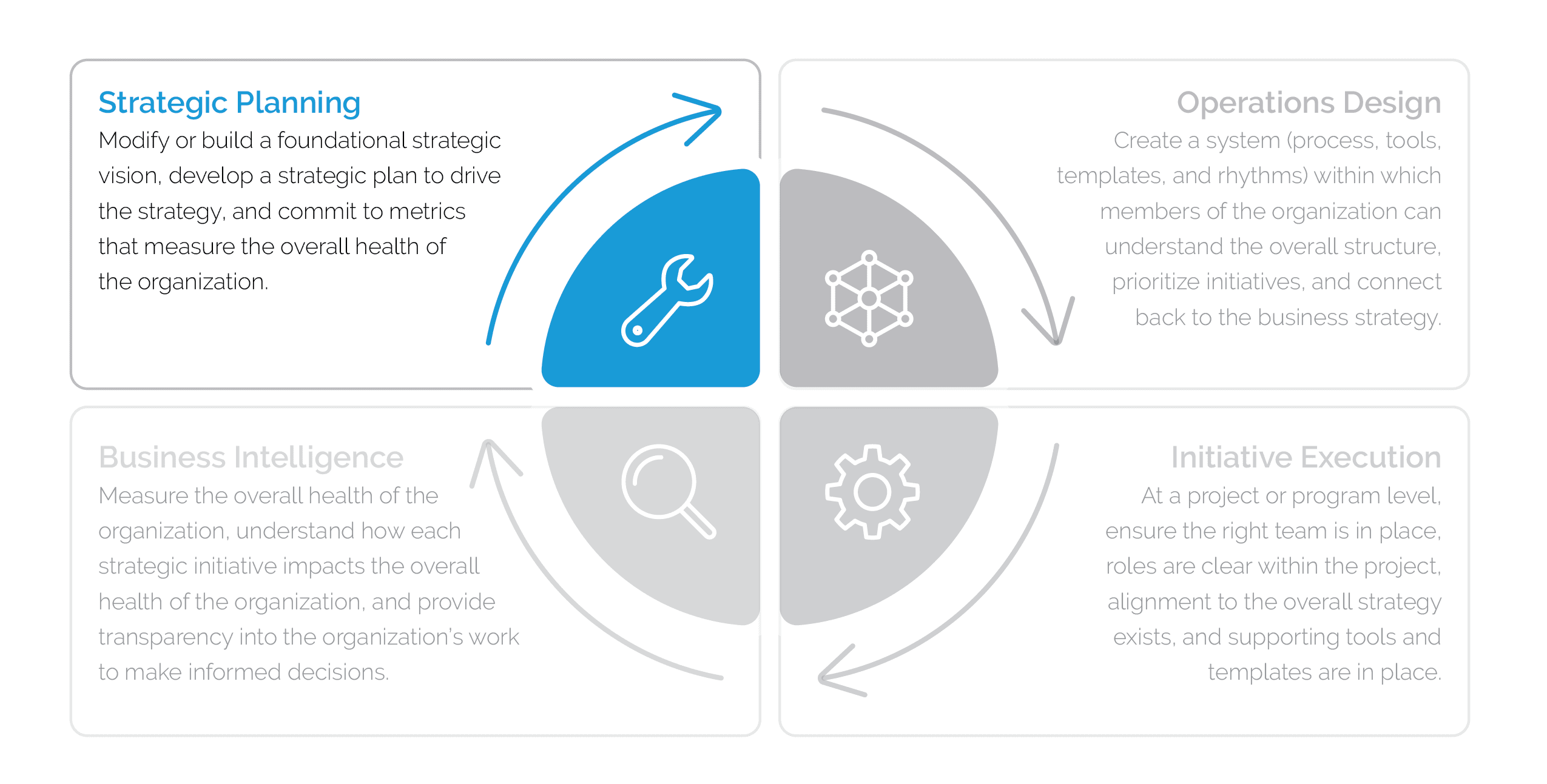

Strategy And Governance Eitbok

Capacity Planning Meaning Classification And Its Goals

1

Capacity Management

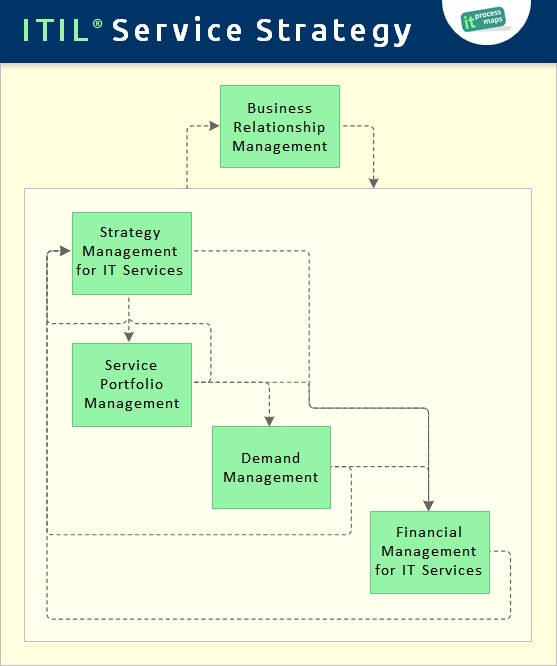

Itil Service Strategy It Process Wiki

Capacity Utilization Definition Example And Economic Significance

What Is Capacity Management Definition And Faqs Omnisci

A Complete Guide To Product Management Roles Updated For 21 Aha

Capacity Planning Meaning Strategies Importance And Procedure

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Digital Transformation Strategy The Bridges To Build

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Strategic Analysis Your Ultimate Guide Marketing Templates

Evaluating Capacity Development Better Evaluation

Capacity Management

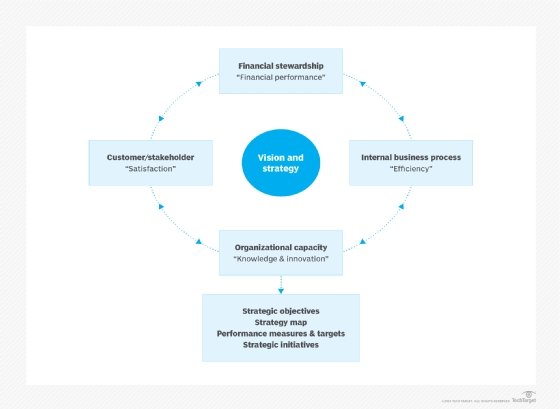

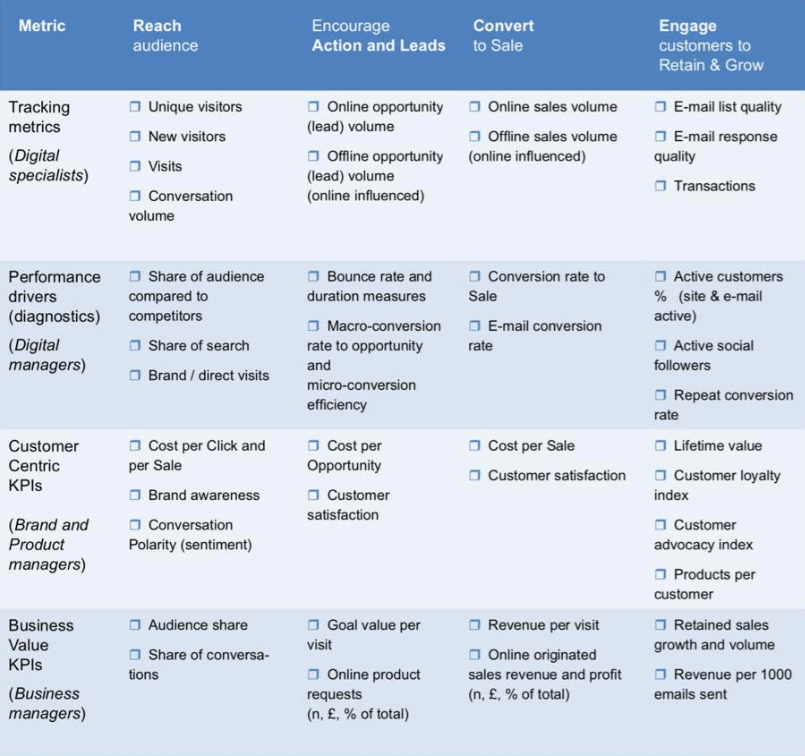

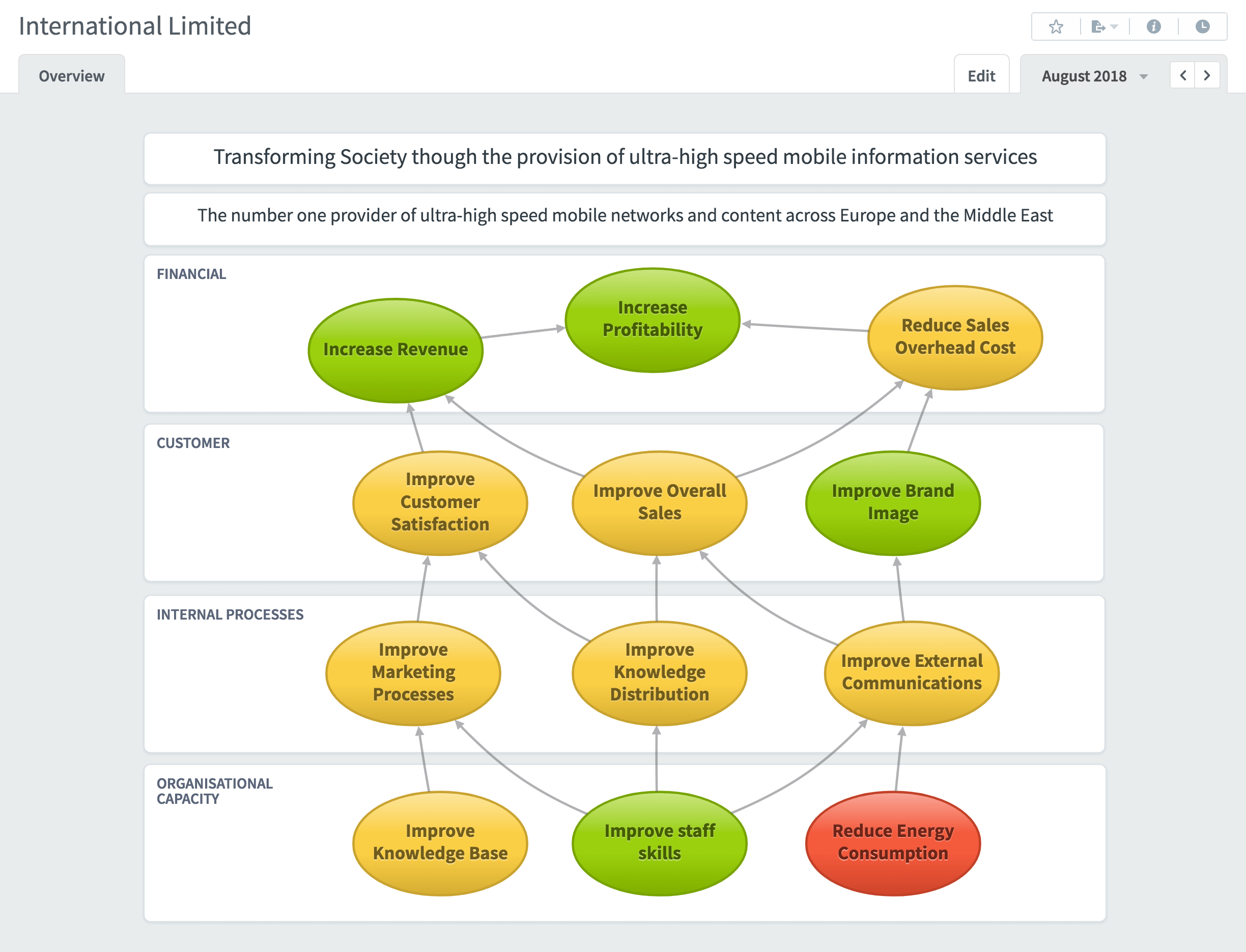

Balanced Scorecard What Is The Balanced Scorecard

Capacity Management

Porter S Generic Competitive Strategies

Excess Capacity Overview Causes And How To Monetize It

Capacity Planning Everything You Need To Know Opensense Labs

What An Effective Capacity Planning Process Looks Like In 21

Capacity Planning Meaning Strategies Importance And Procedure

Capacity Planning Everything You Need To Know Opensense Labs

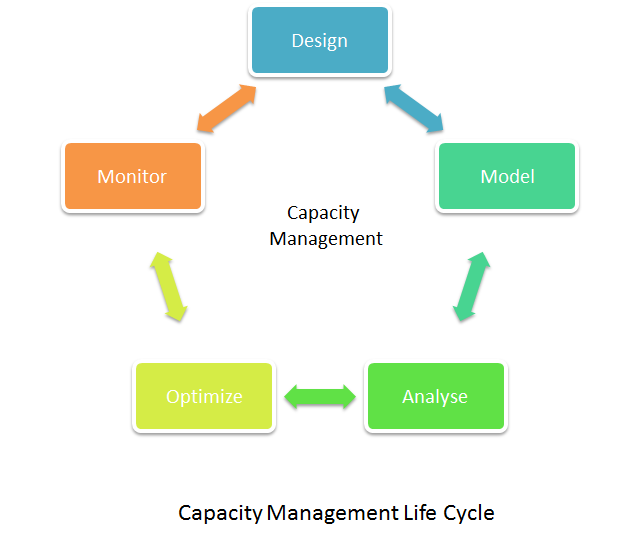

Itil Capacity Management Bmc Software Blogs

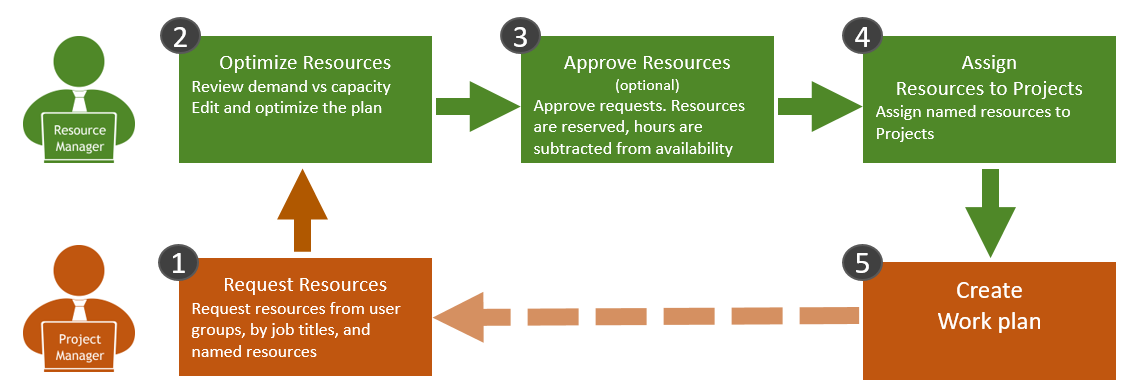

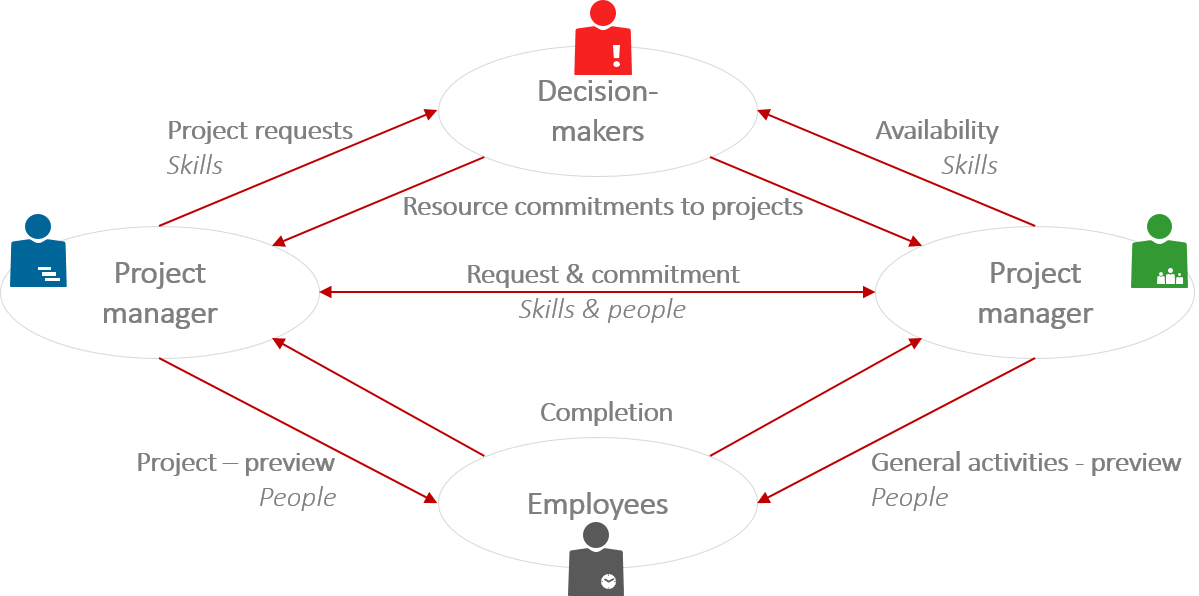

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Ability Capability Capacity And Competence Bpi The Destination For Everything Process Related

What An Effective Capacity Planning Process Looks Like In 21

Achieving High Performance Low Cost Logistics Kearney

Capacity Planning Everything You Need To Know Clicktime

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

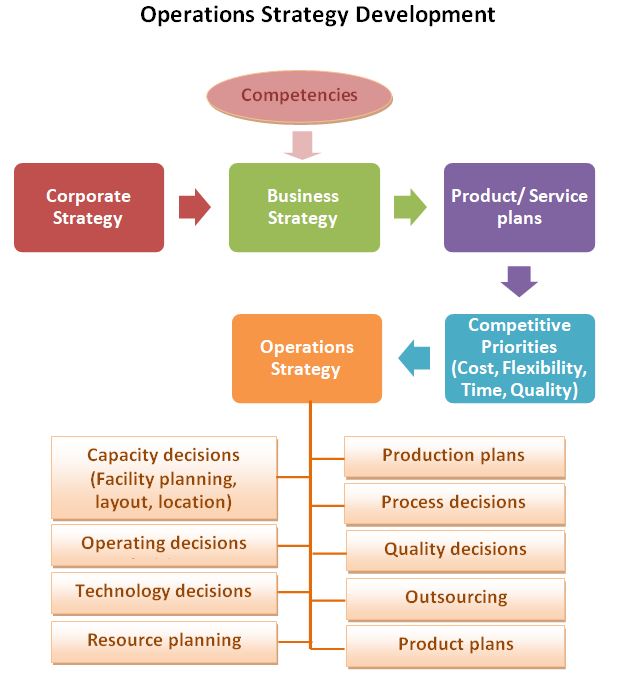

Operations Strategy With Examples Studiousguy

Ppt Chapter 11 Strategic Capacity Management Powerpoint Presentation Id 9169

Quick Guide How To Write A Strategic Plan Smartsheet

How To Define Product Features With Examples Aha

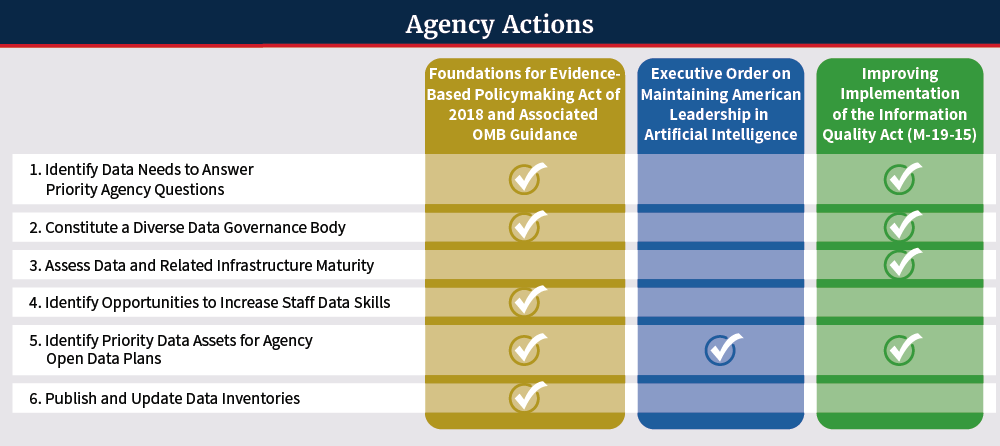

Action Plan Federal Data Strategy

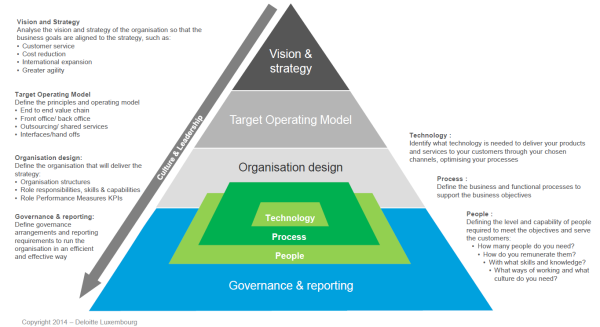

Think Insights Tom What Is A Target Operating Model

Capacity Utilization Rate Definition Meaning Importance Marketing91

Solved Page 2 Concept Check Questions Please Answer Foll Chegg Com

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Supply Chain Management Wikipedia

Evaluating Capacity Development Better Evaluation

What Is Organizational Development A Complete Guide Aihr Digital

Operations Strategy Handbook

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

3

Strategic Positioning Strategy For Executives

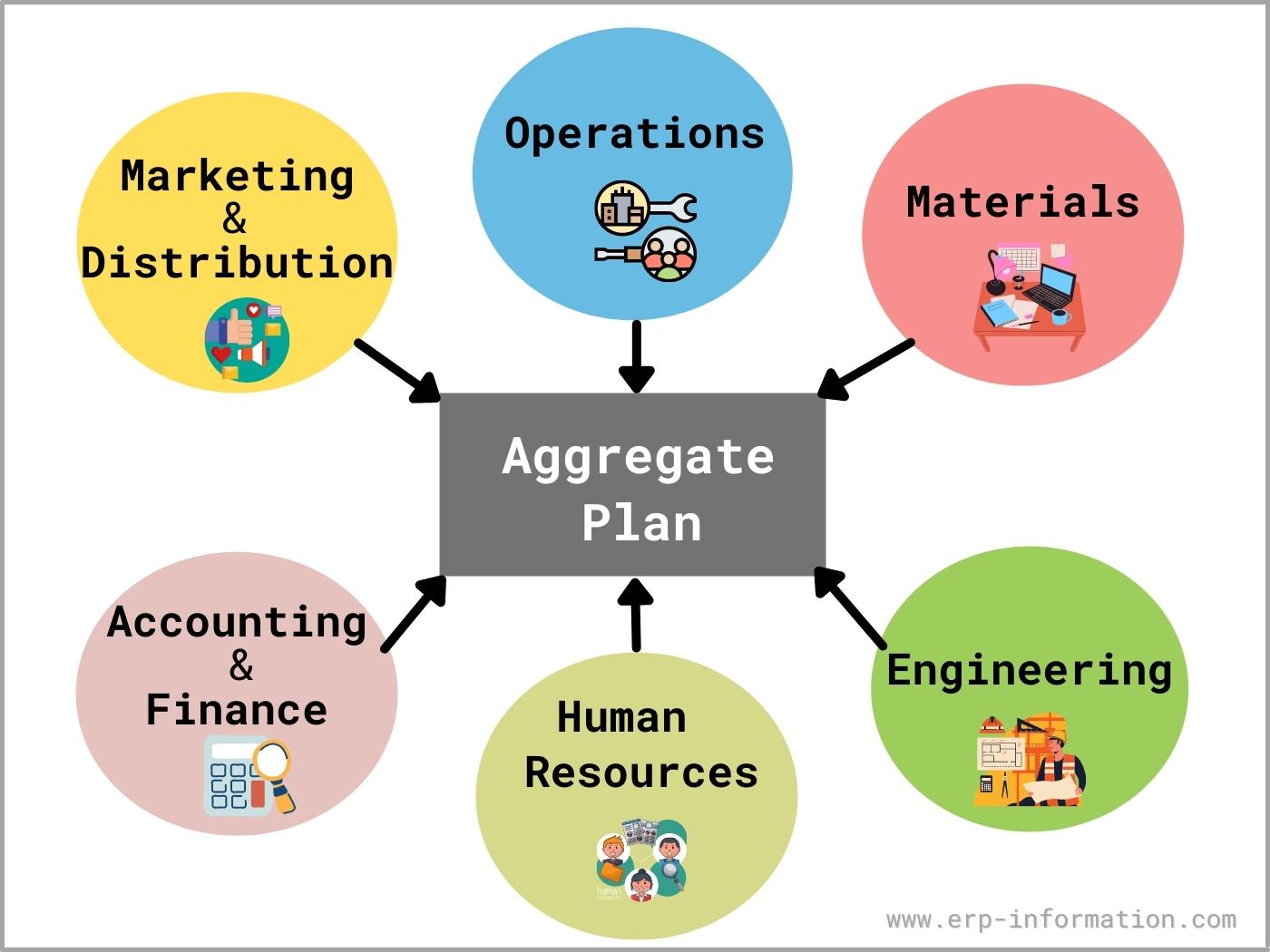

Aggregate Planning Definition Importance Strategies Management And Advantages

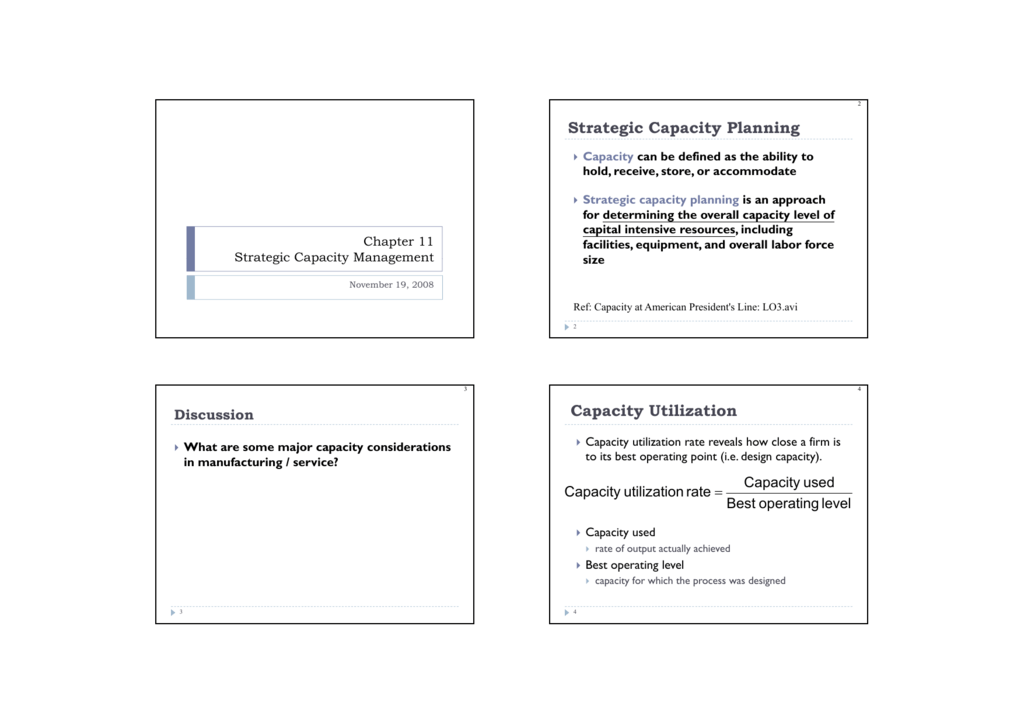

Strategic Capacity Planning Capacity Utilization

Production Management Definition Importance And Software Solutions

What Is Corporate Level Strategy Definition Salient Features And Classification Business Jargons

Operations Strategy With Examples Studiousguy

Strategy Under Uncertainty

Strategic Themes Scaled Agile Framework

Increase Manufacturing Production Capacity Vorne

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

Capacity Planning Everything You Need To Know Clicktime

Operations Management Definition Principles And Strategies

Everything About Capacity Planning Strategies Its Benefits

Evaluating Capacity Development Better Evaluation

Operations Strategy Capacity Strategy Ppt Video Online Download

3 Types Of Capacity Planning Strategies Valq

Strategic Management Wikipedia

Strategic Planning Wikipedia

Strategic Positioning Strategy For Executives

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Management It Process Wiki

Evaluating Capacity Development Better Evaluation

0 件のコメント:

コメントを投稿